How we helped

Three CEOs in a year. A 45% drop in stock in two months. Negative EBIT. A big new product that was behind schedule and a drag on liquidity. When AlixPartners was brought in by an aircraft manufacturer to turn things around, the press was dire and consumer confidence in the brand had spiraled downwards.

Across financials, products, operations, and company culture, our team identified key areas that were ripe for reinvention. From a fragmented supplier base, to a failure to integrate and synergize parts of the company, we recommended drastic changes to transform the company’s cost story. These included:

- A switch from top-down cost-driven decision-making to a bottom-up ideas pipeline.

- The breakdown of large transformation modules into focused sub-areas that optimized procurement, lean manufacturing, capex, and on.

- Inducing a sense of urgency to deliver financial results fast and propel the next stage of development.

- A sustained campaign to get and hold buy-in from the board, with bimonthly reporting and a one-team mentality across the firm.

Within three years we had exceeded most targets, beating the cash savings target twice over with €10 million derived from cash crisis management ahead of the deadline. Smart buying, reduced overhead, and a reboot to manufacturing competitiveness saw EBIT leap beyond the €2.1 billion goal to €2.9 billion. Importantly, these changes set up the manufacturer to accelerate growth after restoring customer confidence and empowering teams and firm leadership to make fleet-footed decisions.

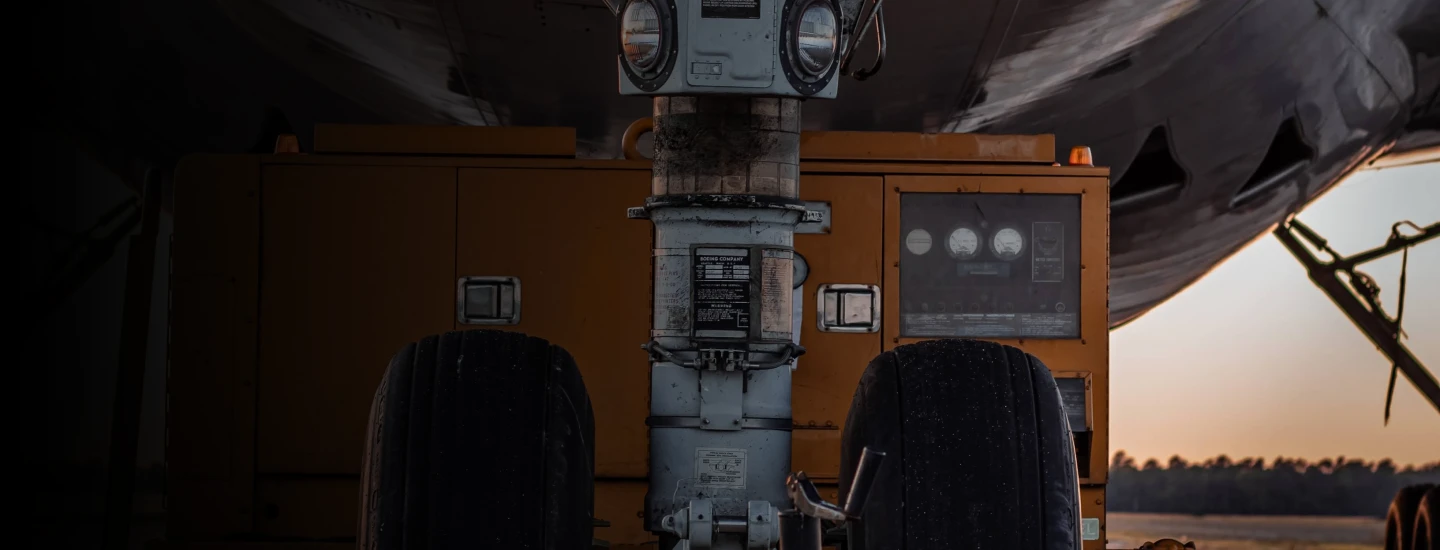

Since that inflection point, AlixPartners has been the partner of choice to execute performance improvement projects, including complex data analytics and predictive modeling for new components. Following our engagement, it was wheels-up for the next era of aircraft innovation.

400%

share price increase

over 5 years